Describe the Key Tools Used in Lean Production

How does 5S help. Lean techniques are typically used in a production environment and most examples in Lean training courses will focus on applying Lean techniques in these kinds of processes.

Lean Manufacturing A Modernized Management Model

Professionals using this repeatable method will analyze a problem or an opportunity to change test a hypothesis review and analyze the results and implement the plan if successful.

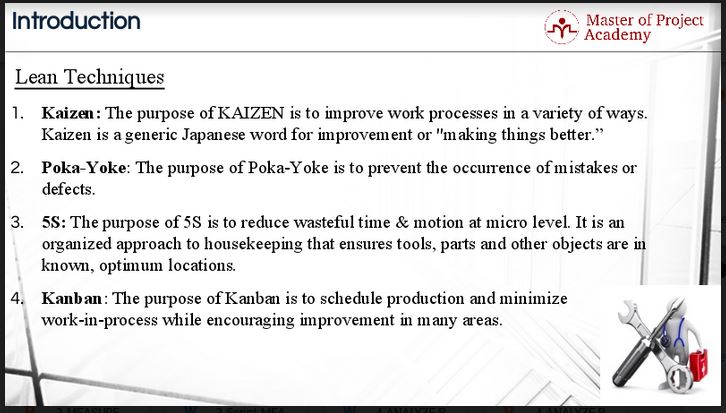

. In a Lean manufacturing environment a part is only created or purchased if there is a Kanban card for it. Lean Conceptseliminating waste to improve the flow of information and materialAnytime the flow stops we have waste. Error Proofing also known as Poka-Yoke.

Information technology telecommunications sales healthcare finance and even the military have used Lean Six Sigma to transform processes with business process management ideas often proving the key the key to staying ahead in todays busy marketplace. Is an operating philosophy of waste reduction and value enhancement. It ensures whether each item required in the work place is in its position or it has to be modified or replaced by a new item.

Error and Mistake-Proofing also known as Poka Yoke is one of the powerful Lean tools used to ensure products and processes are completed correctly the first time. Lean management is one of the top tools that eliminate waste in any process. Seiri Sort Remove all unnecessary items for your current production leaving only what is necessary.

Seiso Shine Clean and inspect your work area and everything in it every day. The following are five 5 key characteristics to consider in the development and implementation of an SRM system. The five principles are considered a recipe for improving workplace efficiency and include.

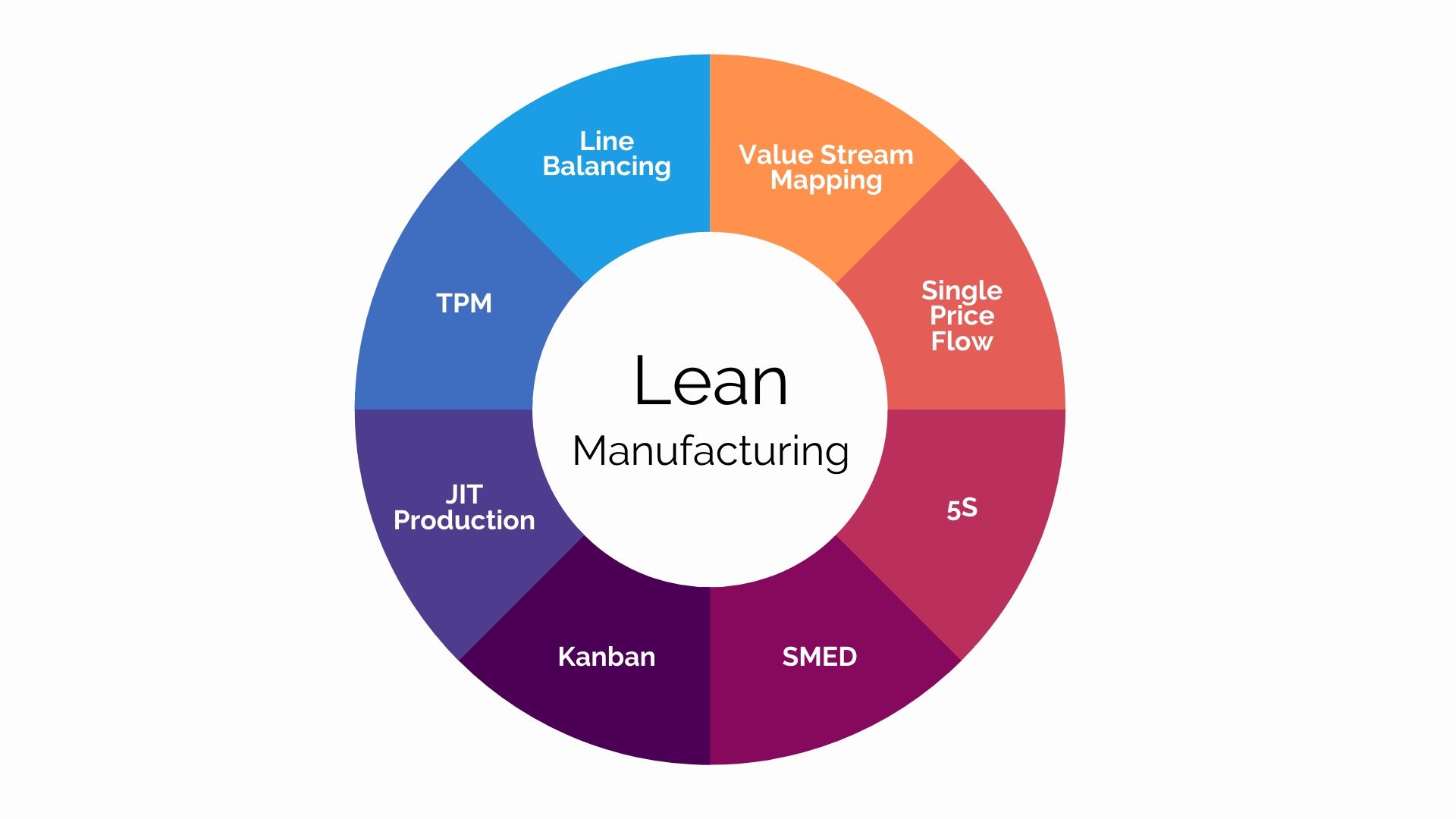

Jidoka Autonomation Jidoka is another Lean manufacturing tool of Japanese origin. There are a variety of tools that can be used to help implement a lean management system these include. Though there are some differences between the two frameworks the underlying philosophies behind Lean and Six Sigma complement each other exceptionally well.

Seiton Set In Order Organize remaining items and label them accordingly. The Gemba is one of three important Lean manufacturing tools that can help leaders approach their role with greater humility as they sharpen their analytical skills. 25 Lean Manufacturing Tools 5S What is 5S.

The PDCA cycle is a key element of Lean managementthis tool helps companies transition to continuous improvement. Organize the work area. 5S a methodology for organising the workplace.

Kanban is a visual signal thats used to trigger an action. The 5 Ss are. The Bottleneck Analysis is a potent Lean tool if your company is suffering due to a lack of an organized structure.

Overall Equipment Effectiveness OEE Plan Do Check Act PDCA Error Proofing. Principles and Tools Lean Production includes on the one hand a strategy which depends on a set of tools and on the other hand the Lean thinking which focuses both internally by reducing costs and externally to increase customer satisfaction. Value Stream Mapping VSM Develops a visual map illustrating the plants material and information flow that provides the vision and path to a Lean transformation.

Lean Culturea successful and sustainable Lean. The House Of Lean Production In The Context Of The Literature Review Download Scientific Diagram Share No comments for Describe the Key Tools Used in Lean Production. The Kanban board is a tool for mapping every step of your process and therefore visualizing your teams value stream.

It allows you to see waste and focus improvement kaizens more strategically on areas in the Value Stream. Key tools used in lean production. Companies that successfully embrace lean production methods can achieve impressive improvements in their.

Write standards for above. Womack and Jones defined the five principles of Lean manufacturing in their book The Machine That Changed the World. Error and Mistake Proofing can be focused on a single machine or process using the talents of only a few people or it can become a broad undertaking addressing many issues simultaneously.

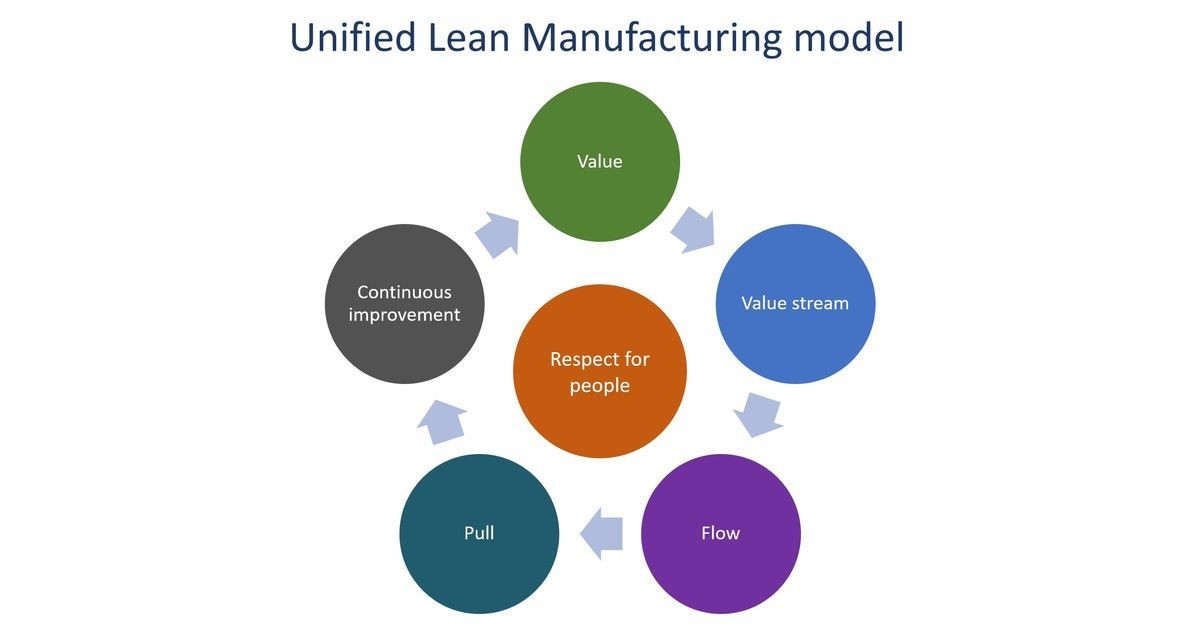

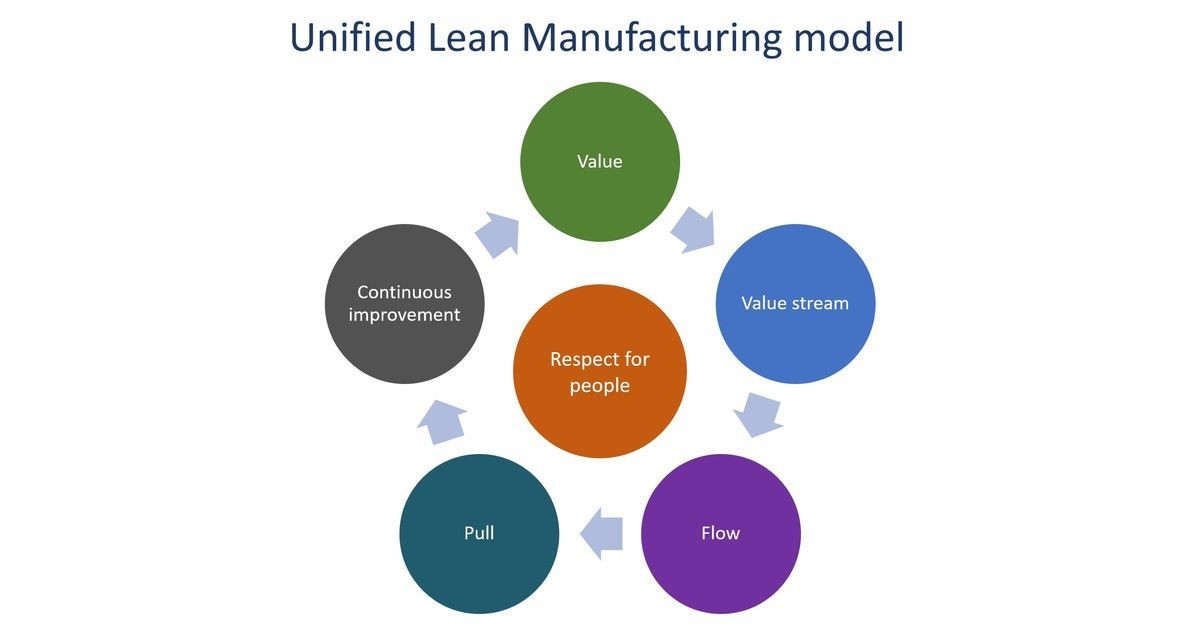

Lean Manufacturing Tools Used. Lean Planningthe linking together of the organizations annual and strategic goals with the Lean activities that will achieve these goalsThis linking is an activity called PolicyCompany Goal Deployment. 1 defining value 2 mapping the value stream 3 creating flow 4 using a pull system and 5 pursuing perfection.

Automation integration visibility collaboration optimization. Kanban is a Lean manufacturing technique that was developed to reduce the waste of overproduction. Regularly apply the standards.

Clean and inspect work area. The term lean production refers to the set of tools and techniques used to streamline and improve a companys production systemWith its roots in the Toyota Production System lean production aims to boost productivity while reducing waste. Kanban Boards to visualise the workflows.

Control Charts to check workflows. Some other popular lean tools to add to the list are. January 2 2022 January 9 2022 Leanie Louw Six Sigma.

When used together the two are referred to as Lean Six Sigma a process. The 5Ss refers to the arrangement of work place organization and its consistency. The word Kanban roughly translated means card you can see in Japanese.

The 5Ss are Seiri Sort. The names of these Lean tools are self-explanatory. The objective of this multi-dimensional approach is the reduction of.

The standard lean manufacturing tools. These are just a few of the lean tools. Lean tools are designed to eliminate invaluable processes while Six Sigma focuses on lessening variation within a process.

Lean Manufacturing Tools and Techniques With companies and manufacturing units getting upgraded to newer and more efficient practices it becomes evident that theres a great need for manufacturing tools and techniques to improve this situationManufacturing is gaining momentum as the world market is progressing through each day. Eliminate that which is not needed. Developed as part of the Toyota production system which laid the foundations of Lean management the basic Kanban board is a vertical flat surface divided by columns for the three primary states of any assignment.

Lean Manufacturing Training Materials Lean Factories

No comments for "Describe the Key Tools Used in Lean Production"

Post a Comment